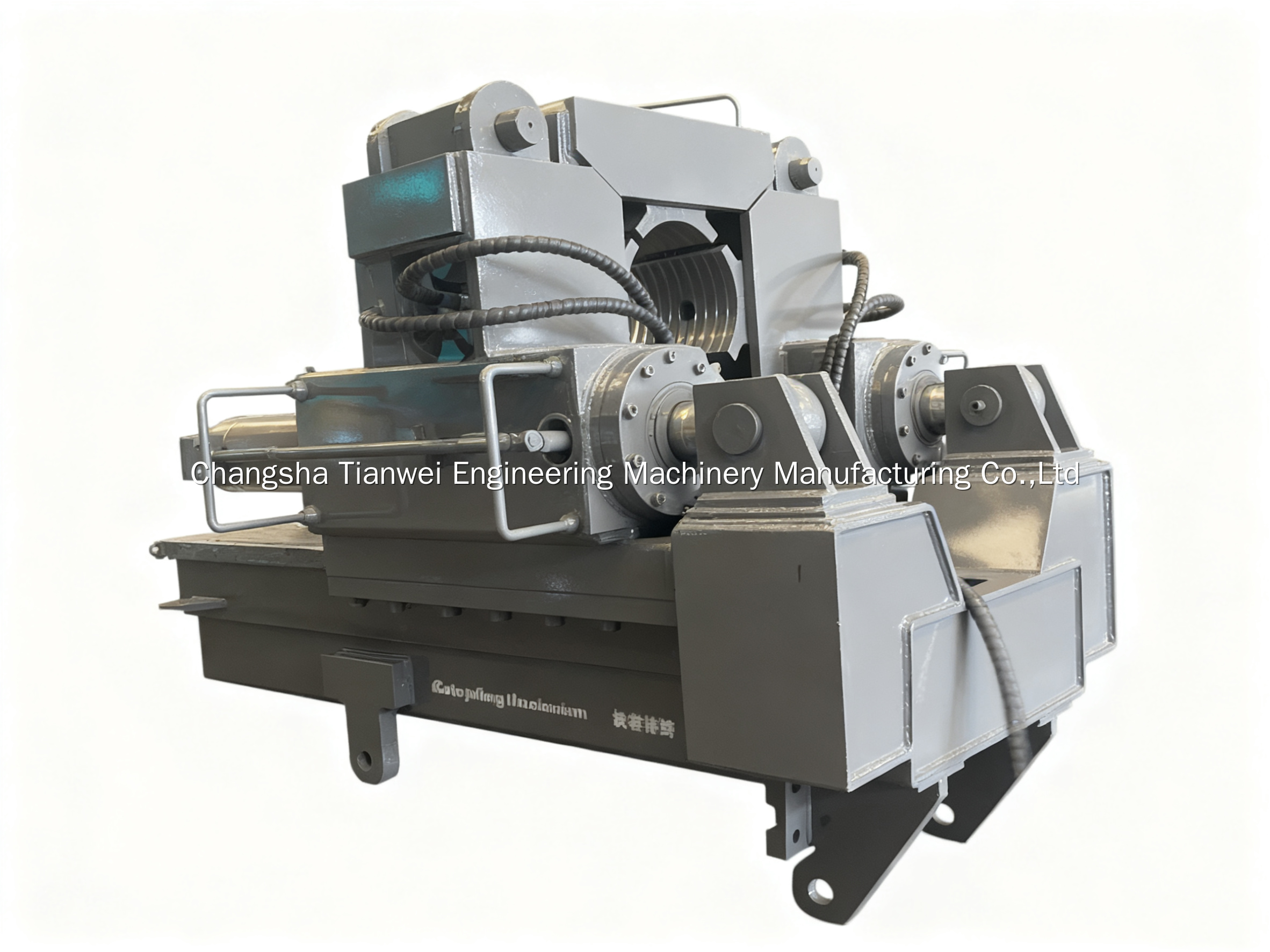

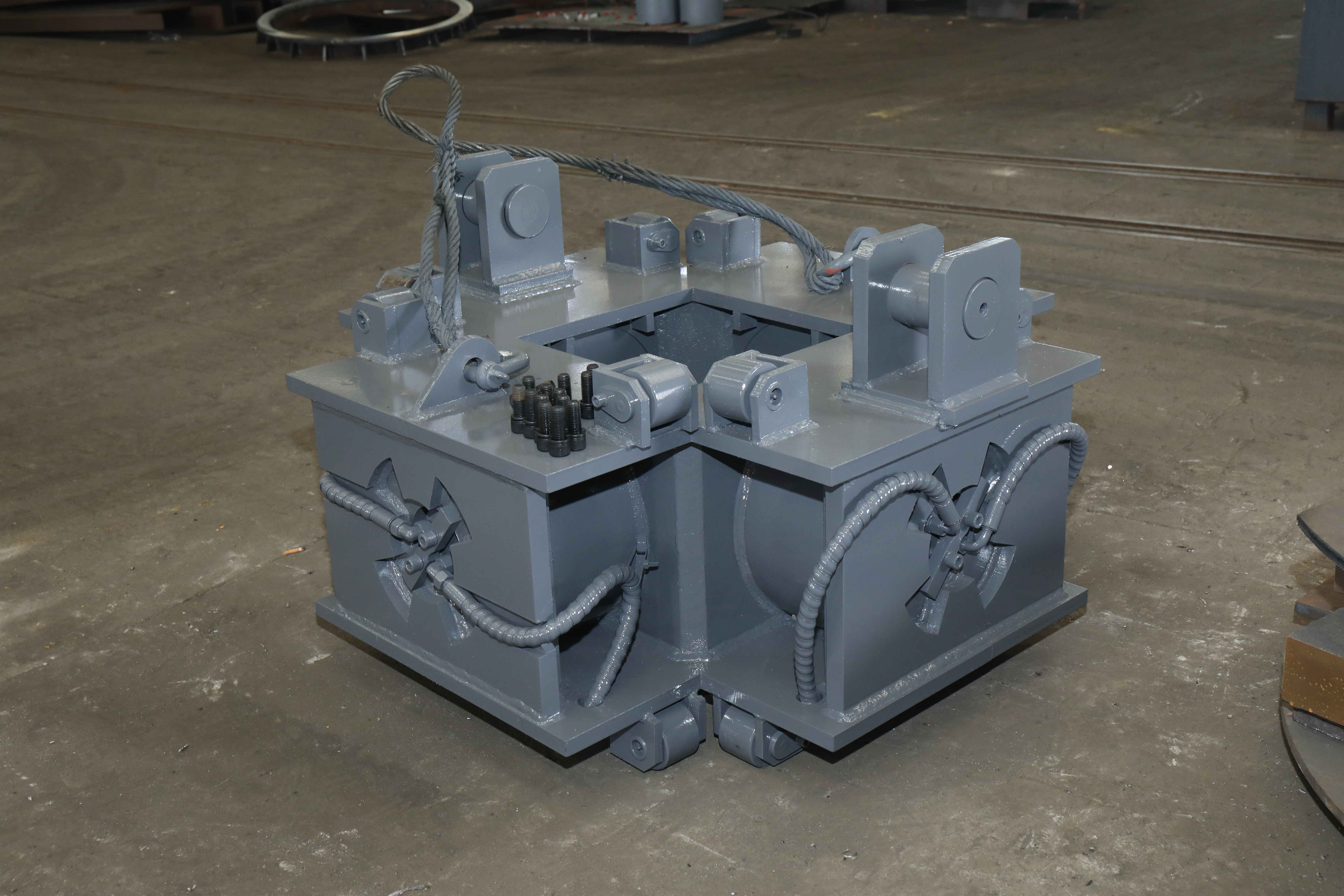

In the field of pile driving machinery construction, clamping jaws, as core wearing parts, have long been a major concern for project parties due to their wear rate and maintenance costs. Especially under complex working conditions such as soft soil and clay in Southeast Asia, conventional jaws, which lack sufficient wear and deformation resistance, need to be replaced every 300-400 hours on average. This not only incurs high accessory costs but also directly slows down the construction progress due to frequent shutdowns for maintenance. Recently, the forged clamping jaws used by Changsha Tianwei Machinery (T-WORKS) have achieved a "50% reduction in maintenance costs and doubled service life" through material-side innovations.

T-works Forging Accessories of Clamping Jaws: Maintenance Costs Cut by 50%, Service Life Doubled

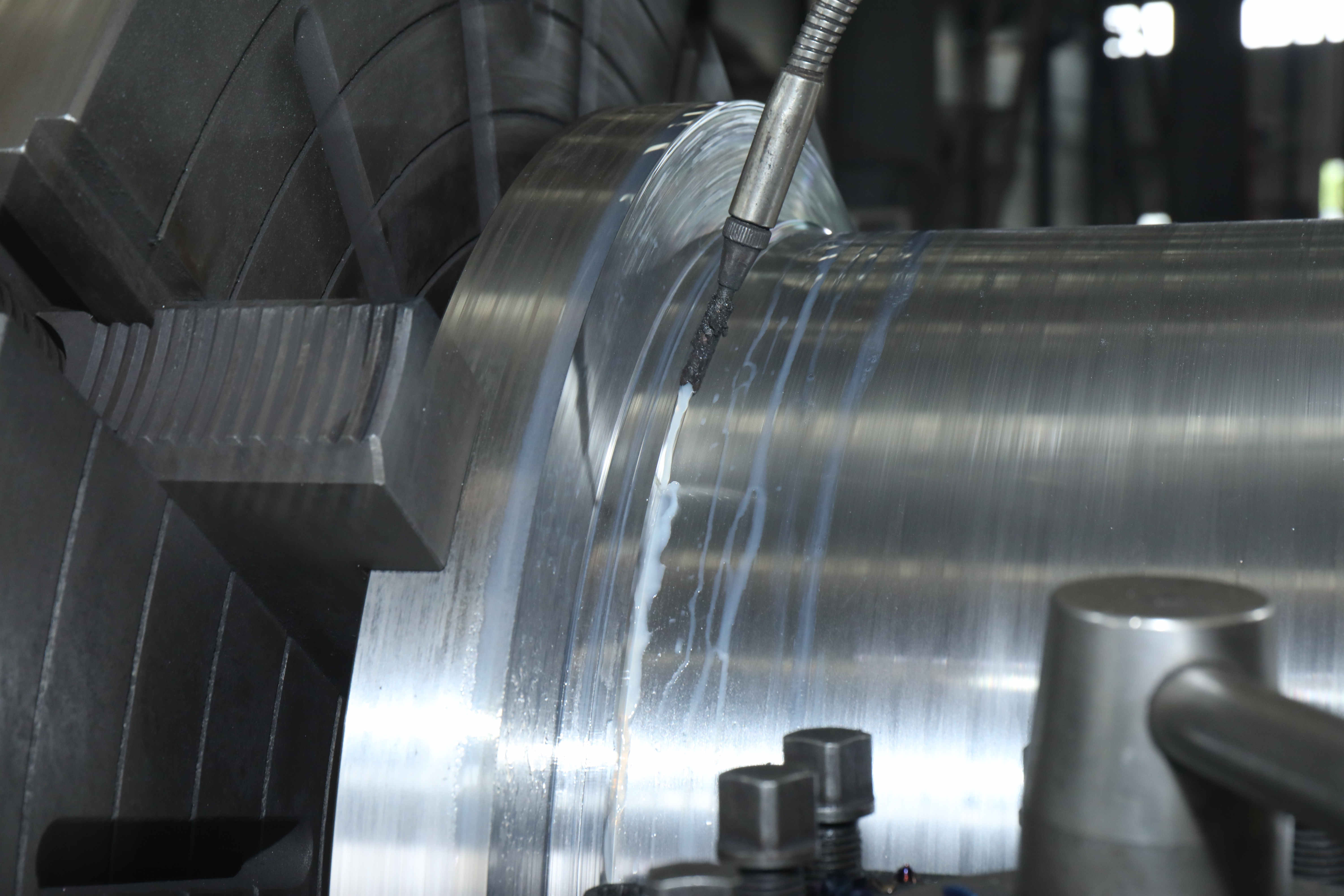

Targeting the pain points of jaw wear, T-works R&D team has upgraded the technology from the source. On the material front, high-strength alloy forgings are adopted, followed by precision forging and multiple rounds of surface hardening treatment. This raises the surface hardness of the jaws to HRC 58-62, improving their wear resistance by 120% compared to conventional products in the industry. In terms of structure, the tooth profile design of the jaws has been optimized, using a "bionic tooth pattern that fits the arc of the pile body." This reduces the concentration of local stress during clamping, avoids early cracking caused by uneven force, and enhances adaptability to piles of different specifications—compatible with precast pipe piles, square piles, H-beam piles, and other pile types.

According to laboratory data from Tianwei Machinery and feedback from on-site projects, the service life of T-works clamping jaws is twice that of ordinary jaws. The comprehensive cost of maintenance frequency, accessory procurement, and labor maintenance has decreased by 50%.

More importantly, reduced maintenance frequency directly cuts down equipment downtime. Taking a pile foundation project with a 12-month construction period as an example, using Tianwei’s jaws can reduce the number of maintenance shutdowns by 4-5 times, saving a total of over 120 hours of downtime. Based on a daily construction output value of RMB 20,000 per piece of equipment, this can create an additional RMB 2.4 million in output value, delivering significant indirect benefits.

In response to differences in construction environments across regions, Tianwei also provides customized jaw solutions. For the high-temperature and high-humidity environment in Southeast Asia, the anti-rust coating of the jaws is optimized; for the strict environmental standards in European and American markets, a lead-free coating process is adopted. At the same time, it supports adjusting the jaw size and tooth profile according to the customer’s equipment model and pile specifications to ensure seamless adaptation to existing equipment. Currently, this type of clamping jaw has been widely used in infrastructure projects in multiple countries in Southeast Asia and East Asia, with a customer satisfaction rate of over 99%.

"T-works has always taken ‘solving customers’ actual pain points’ as the core of R&D. From hydraulic static pile drivers to forging accessories, every product is designed to meet the three core needs of ‘cost reduction, efficiency improvement, and durability’," said a person in charge of Changsha Tianwei Machinery. The company stated that it will continue to deepen technological innovation in core components of pile driving machinery in the future, and empower the high-quality advancement of global infrastructure projects with better products and services.

PRODUCTS