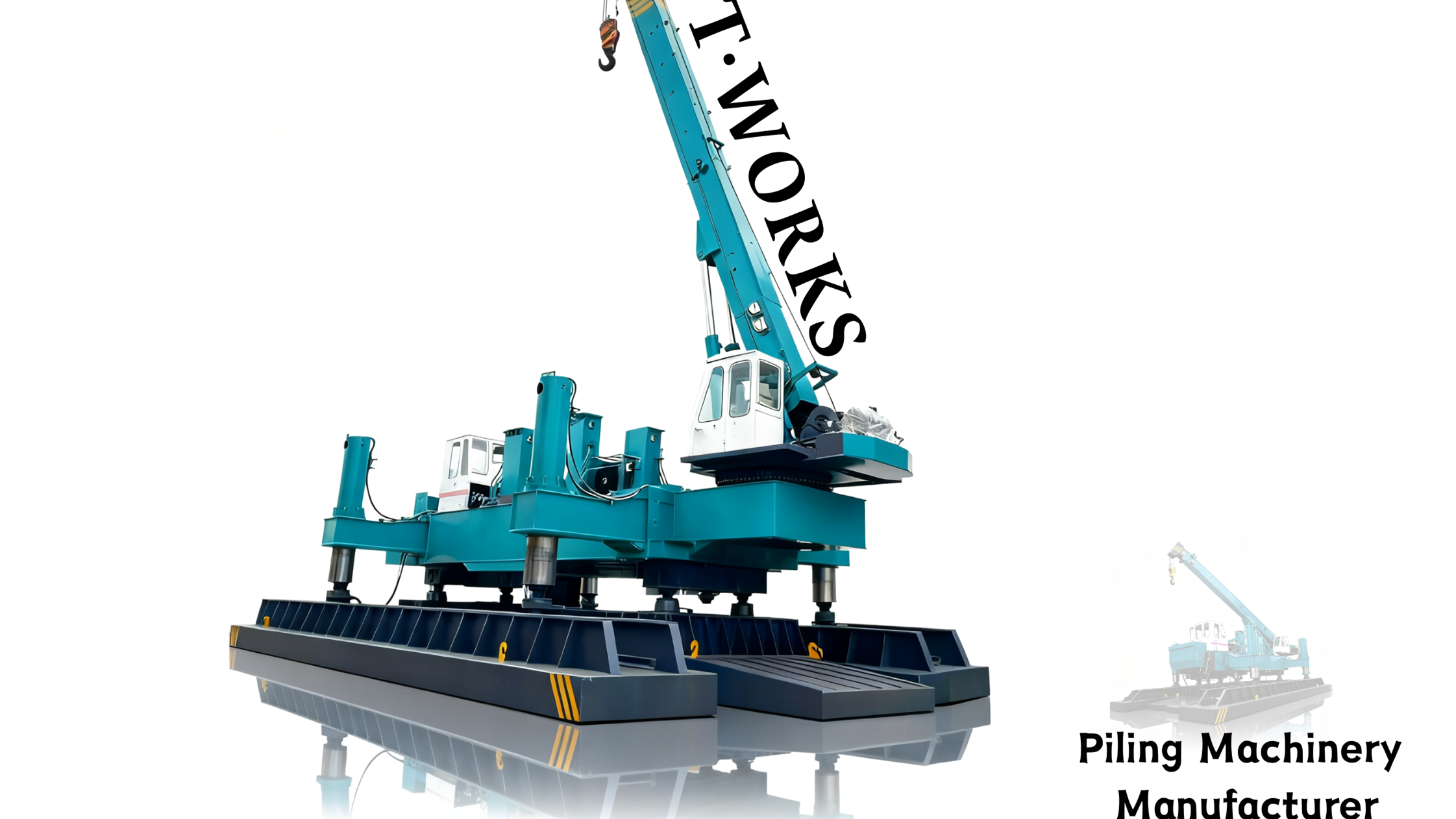

20-Yr Static Pile Expertise! T·WORKS HSPD: Vibration-Free, Quiet, All-Scenario, Global Infra "Green Tool"

Designed from the start to meet the two core needs of "green construction" and "efficient adaptation", T-works ZYC series hydraulic static pile drivers set a technical benchmark in the industry with three key features:

1. Vibration-Free, Quiet, Pollution-Free: "Zero Disturbance" for Construction in Sensitive Urban Areas

Different from the noise and vibration of traditional impact pile drivers, T-works static pile driver adopts a pure hydraulic drive principle. Relying on the counterweight of the machine body and the reaction force of the already driven piles, it steadily "squeezes" piles into the ground — the construction noise is only 55 decibels (equivalent to normal conversation volume), and the vibration value is close to zero, perfectly adapting to three sensitive scenarios:

In projects such as the pipeline renovation in Gulou District, Nanjing, and the renewal of old communities in Guangzhou, construction adjacent to residential buildings still achieved "zero complaints", avoiding noise disturbance to residents

When constructing near hospitals, laboratories, and century-old buildings, the vibration-free feature protects building foundations and precision instruments. For example, in the expansion project of a electronics factory in Huizhou, pile driving within 3 meters of the equipment room did not affect the operation of instruments;

In ecological projects such as wetland restoration and reservoir dam reinforcement, there is no oil leakage or dust pollution, meeting strict global environmental standards. The ZYC360B-CB model of Tianwei was selected for the wetland management project in the Netherlands.

2. Full Tonnage Coverage from 60 to 1260 Tons: Suitable for All Scenarios from "Alley Construction" to "Super Large Projects"

T-works fully understands the differentiated needs of different projects for equipment tonnage, and has created nearly 40 specifications of ZYC series models, ranging from 60-ton light-duty machines to 1260-ton super large machines, adapting to full-scenario construction from "alley pipe corridors" to "cross-sea bridges":

With a minimum body width of only 3.9 meters, they can enter narrow alleys 3 meters wide. Equipped with a "detachable side pile mechanism", the transportation length is reduced by 40%, suitable for "small-space operations" such as urban pipe corridor support and small factory pile foundations

With a rated piling force of 260-680kN, they are suitable for precast square piles/pipes with Φ500-600mm. In projects such as the construction of industrial parks in Shandong and municipal road construction in Xi’an, they achieved efficient operations of "driving 500-800 meters of piles in 8 hours"

With a maximum rated piling force of 12,600kN, they can drive thick-walled pipes with Φ1000mm. Equipped with 6 piling cylinders and differential hydraulic technology, the piling speed is 20% higher than that of similar equipment. This series is selected for "heavy projects" such as large bridge pile foundations in Guangxi and the foundation laying of industrial parks in Ukraine.

3. Details Reflect Strength: Dual Excellence in Durability and Humanized Design

The "strength" of T-works static pile drivers lies in every detail that balances "durability" and "convenience":

Walking wheels and pile clamping jaws all adopt forging technology, with wear resistance far exceeding that of traditional cast steel parts, and service life extended by 3-5 years; the guide wheel of the pile clamping box adopts an eccentric wheel design, which can adjust the gap in real time, controlling the pile verticality error within 0.3% and avoiding "pile damage" and rework;

It has a patent for telescopic leg design. The disassembly and assembly of the long-short boat connection structure is 50% faster than that of peers, and the transportation weight of a single piece is reduced by 30%, greatly reducing hoisting and logistics costs; the cab can be opened from the middle, allowing the boom to pass directly through the body, solving the problem of "difficult transportation in narrow sites";

Optional digital display screen for piling tonnage, crane torque limiter, and stroke protection device, realizing real-time visualization of construction parameters; the remote data transmission function supports real-time background monitoring. A project in Shandong used this function to realize "remote control of construction progress in the office", reducing on-site duty costs.

T-works not only provides "standard models" but also creates flexible adaptive solutions for the "special needs" of different construction scenarios, enabling efficient completion of "difficult and detailed work":

1. Special Design for Side/Corner Piles: No Pressure for "Wall-Adjacent Construction"

Most pile drivers cannot drive piles near walls or foundation pits due to "insufficient distance", but T-works static pile drivers break through this limitation with three innovative designs:

| - The minimum side pile distance is only 0.4 meters (ZYC80 model), and the minimum corner pile distance is 0.8 meters, enabling "wall-adjacent" piling and solving the pain point of "unable to construct near buildings"; |

| - Three types of side pile mechanisms are available: "fixed/hung/inserted". The inserted side pile mechanism can be disassembled during transportation, balancing "construction flexibility" and "transportation convenience"; |

| - The side pile driving force reaches more than 60% of the middle pile, far exceeding the industry average. In a factory foundation pit support project in Huizhou, it successfully drove Φ400mm square piles 0.5 meters away from the wall. |

2. "Full Compatibility" for Pile Types: One Equipment Replaces Multiple Ones

Without frequent equipment replacement, T-works static pile driver can adapt to almost all mainstream pile types by replacing the pile clamping jaws:

| - Precast concrete square piles (maximum adaptation to Φ650mm), thick-walled pipes, thin-walled pipes (maximum adaptation to Φ1000mm); |

| - Special pile types such as H-shaped steel piles and irregular steel piles; |

| - In a project in Indonesia, the same ZYC460 model successively drove Φ500mm pipes and H-shaped steel piles by replacing jaws, reducing equipment scheduling costs. |

3. Global Customized Solutions: Adapting to Complex Geology and Scenarios

For the special geology and construction standards of overseas projects, T-works provides "one-on-one" customized services:

| - Geological adaptation: Customized "anti-corrosion coated body" for the Dutch wetland project, increasing salt corrosion resistance by 5 times; added "high-pressure water jet auxiliary system" for the sand layer project in Malaysia, reducing pile end resistance by 30%; |

| - Scenario customization: For the ultra-low-altitude factory project in Ukraine, the guide frame of the ZYC360 model was modified to a detachable type, reducing the equipment height to 2.8 meters to meet the 3-meter clear height construction requirement; |

| - Standard adaptation: The products have passed the ISO9001:2000 quality management system certification, complying with EU CE, Southeast Asian TISI and other international standards, and can be put into use overseas without secondary modification. |

T-works knows well that "good equipment" requires "good service". Relying on a global marketing and after-sales network, T-works implements a "zero-distance service" strategy to relieve customers of worries:

| - Pre-project support: A professional team provides geological survey and construction scheme design; |

| - Training empowerment: Free training for customers’ operation, maintenance, and construction personnel to ensure "quick start" after equipment arrival; |

| - After-sales response: The hotline is on standby 24 hours a day, responding to faults within 2 hours and sending personnel to repair on-site within 48 hours; overseas, local service points in Malaysia, Singapore, etc., realize "nearby after-sales service". The Indonesia project once set a record of "equipment repair in 36 hours"; |

| - Lifelong tracking: Establish customer files, conduct regular return visits to understand equipment usage, and provide spare parts replacement and technical upgrading services to ensure long-term stable operation of equipment. |

From urban pipe corridors to overseas bridges, from wetland restoration to industrial parks, T-works ZYC series hydraulic static pile drivers, with 20 years of technical accumulation, full tonnage coverage, and customized services, have become a "green partner" in global infrastructure. Whether you face "construction in sensitive areas", "complex geology" or "overseas adaptation" challenges, Tianwei can provide an integrated solution of "equipment + scheme + service".

PRODUCTS