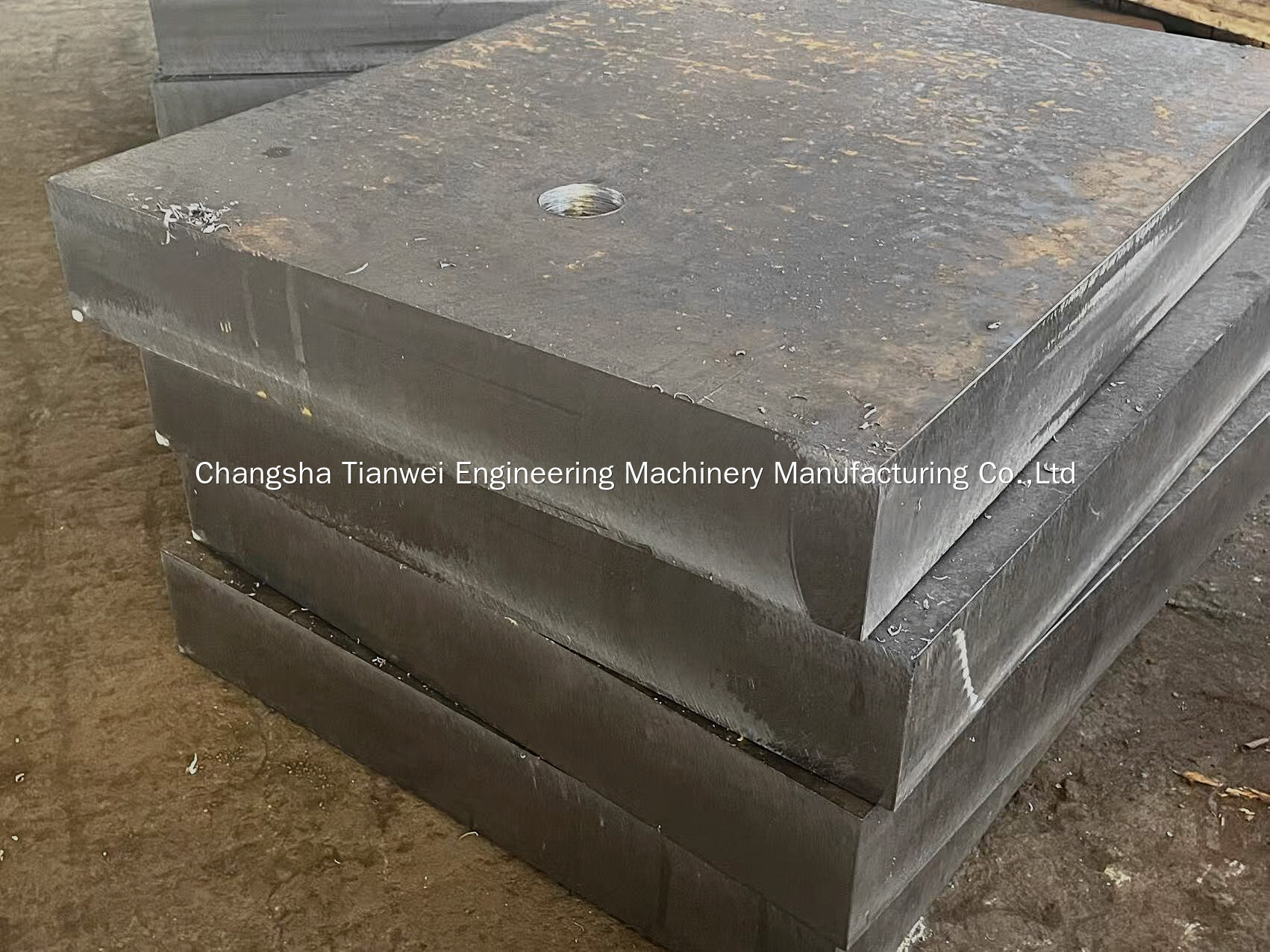

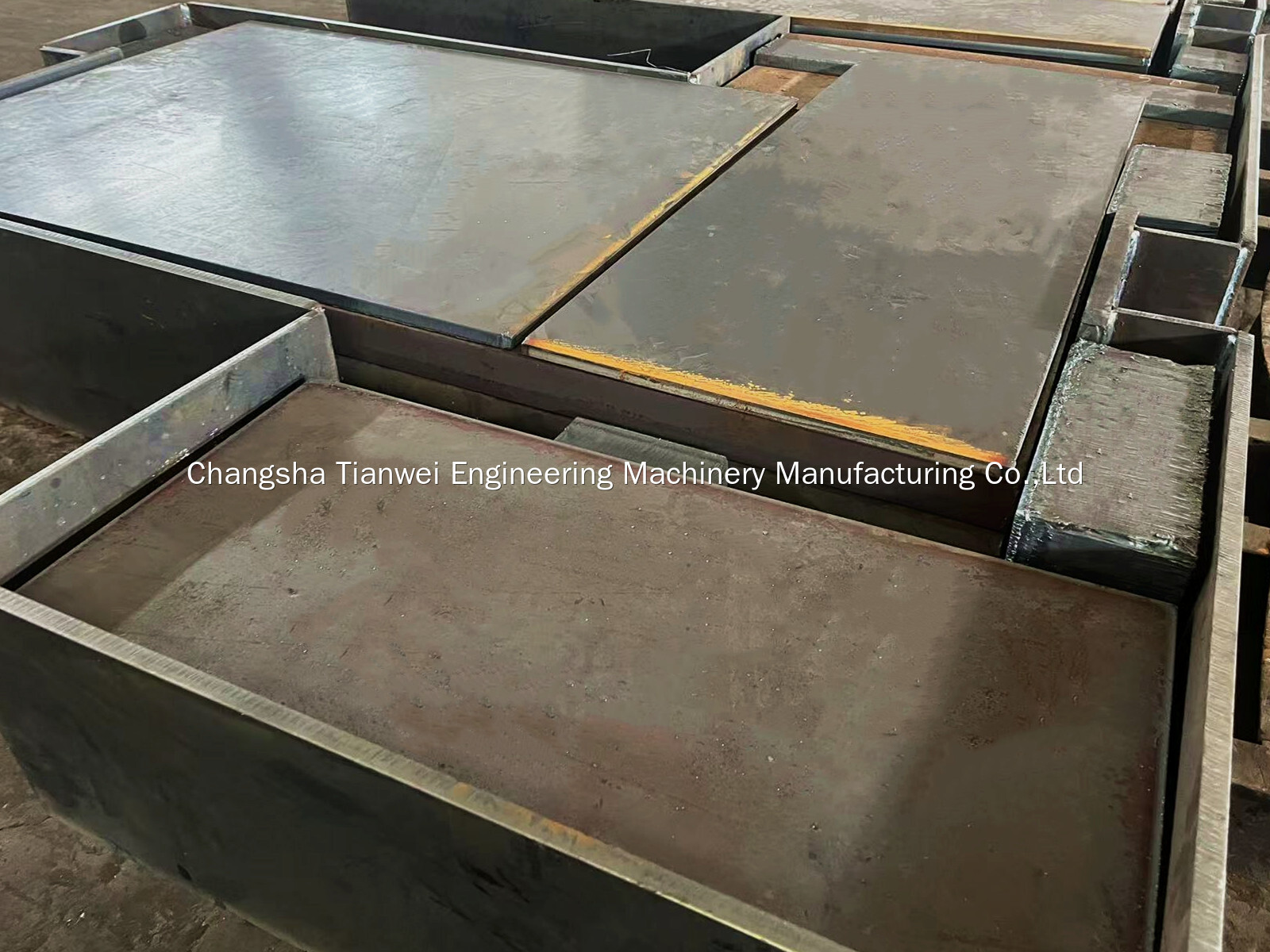

T-works Pile Driver Counterweight Process Fully Unveiled: All-Steel Quality,Steady Global Presence

T·WORKS: Redefining Quality with All-Steel Pile Driver Counterweights

T·WORKS has always rooted its products in "genuine materials and solid craftsmanship."

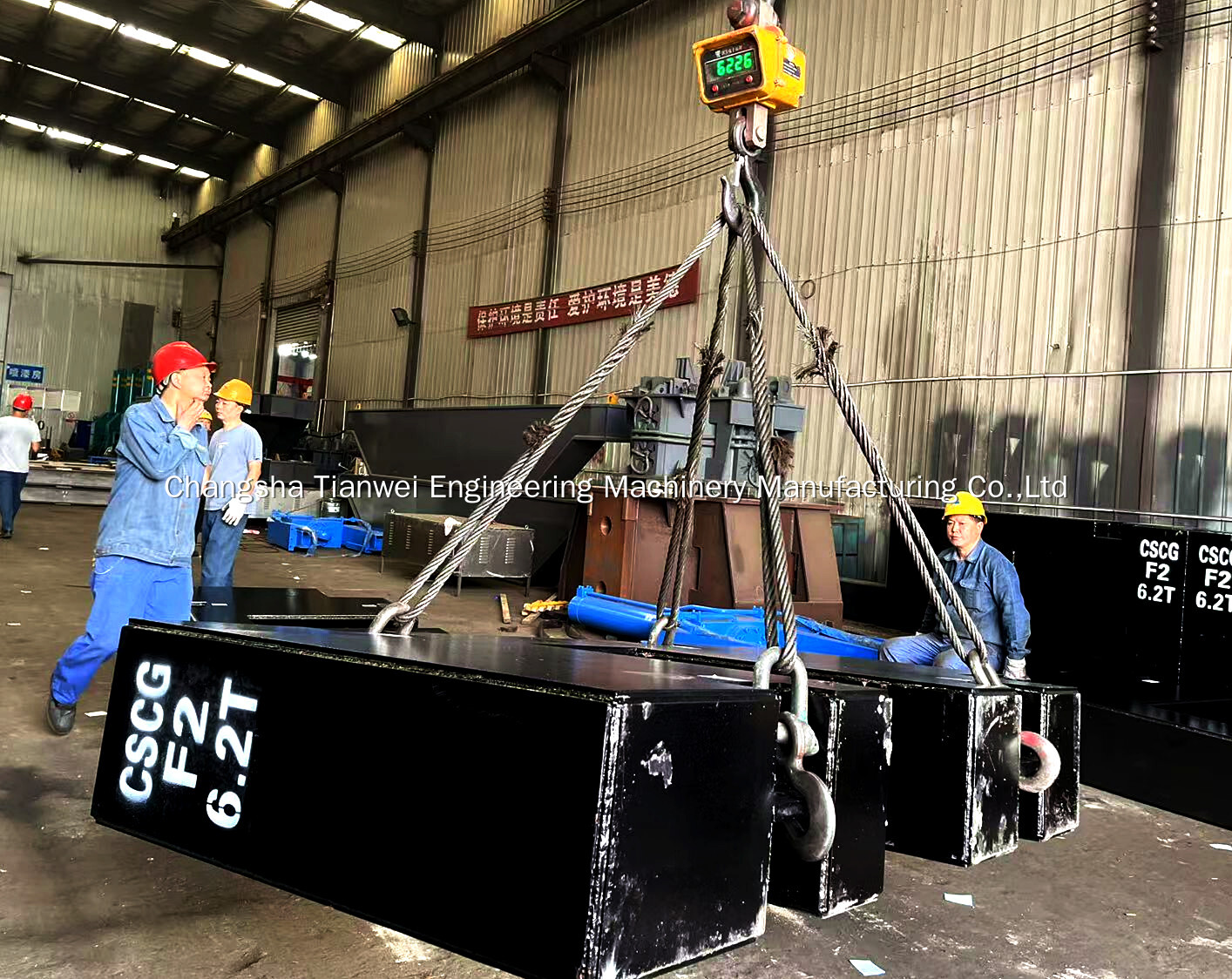

On May 19, the company premiered a full-view demonstration of its pile driver counterweight production process, using a visual journey to interpret the manufacturing philosophy of "100% All-Steel · Quality You Can See," showcasing the hard-core strength of Chinese engineering machinery to global clients.

Defining Quality from the Source At T·WORKS' production base, the "all-steel DNA" of pile driver counterweights runs through every manufacturing step:

True Quality Earns True Trust Thanks to its solid craftsmanship, T·WORKS has recently seen a surge in pile driver orders: 20 trucks of counterweights are being loaded for continuous shipment, with production schedules in high gear.

"After visiting the production line, the sturdiness of the counterweights was clear at a glance,"

said a partner from Malaysia.

"This 'tangible reliability' is exactly why we choose T·WORKS." Currently, pile drivers with all-steel counterweights have been batch-shipped to construction sites in multiple countries, earning "zero-fault" feedback from local engineering teams and becoming a new overseas calling card for "Made in China Quality."

Making Every Trust Traceable To further reassure clients, T·WORKS introduces a Transparent Quality Inspection Service: any client can schedule a factory tour to observe the production process or request third-party testing of counterweight materials. The company also pledges: "All-steel process" — acting on its commitment to ultimate quality.

While the industry still debates counterweight materials, T·WORKS has already delivered its answer with all-steel quality. From Changsha to the world, every counterweight block stands as a symbol of "steadiness," witnessing Chinese engineering machinery's confidence to engage the world with genuine materials and solid craftsmanship.

- FAQCome and witness,to understand Made in China.

![T-works Pile Driver Counterweight Process Fully Unveiled: All-Steel Quality,Steady Global Presence 9]()

- Q1: Are you a manufacturer or a trading company ?what kind of machine do you produce?A: We are a leading manufacturer for kinds of piling machinery with over 20 years experience, located in Changsha, Hunan, China. Our main products arehydraulic static pile driver, Bored pile drilling rig, Hydraulic hammer, Disc Pel-letizer,mini crawler dumper truck etc.

- Q2: What does the hydraulic static pile driver used for?A: The hydraulic static pile driver is used for jacking in the precast cast con-crete pile. Any shape is ok, like square pile, round pile, triangle pile,tubes,H-pile and so on. lt is no noise, no pollution, no vibration during work-ing.lt is static pile driving type for piling .

- Is the customization acceptable ?Yes, we welcome the customization.

![T-works Pile Driver Counterweight Process Fully Unveiled: All-Steel Quality,Steady Global Presence 10]()

PRODUCTS