Inverted Protection Design:

Keeping Construction Dust "Out" and Extending Hydraulic Cylinder Lifespan

The working environment of static pile drivers is often accompanied by pollutants such as dust, silt, and gravel, which can easily penetrate traditional hydraulic cylinders, leading to issues like piston rod scratches and seal failures. This necessitates frequent shutdowns for maintenance, thereby affecting construction efficiency.

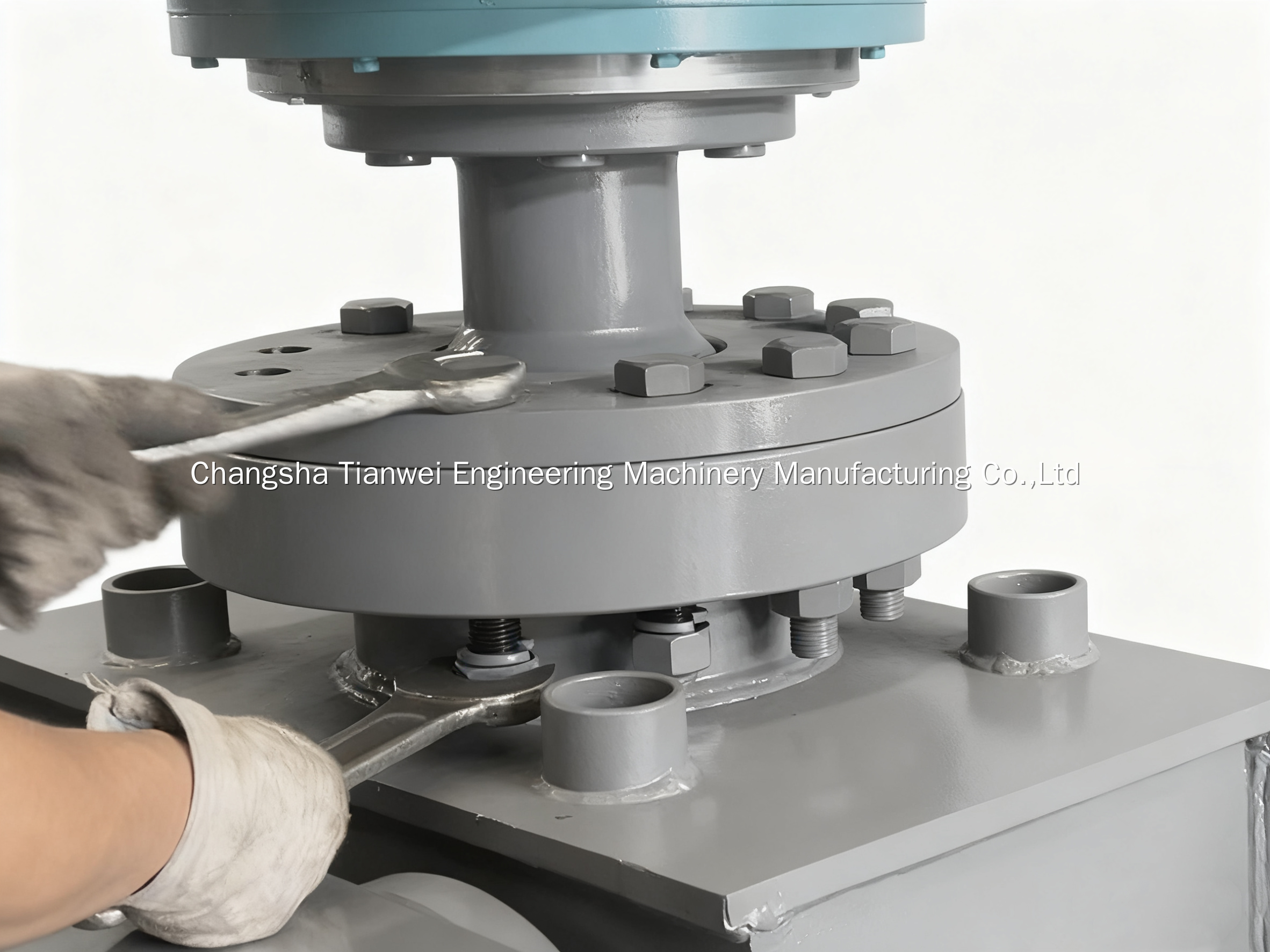

The ZYC series inverted oil cylinder adopts a "piston-in-piston + rigid sleeve" structure: the core moving component, the piston, is fully enclosed within a high-strength alloy sleeve, transmitting the pile-driving force solely through the relative motion between the sleeve and the cylinder body. The annular dust scraping groove on the inner wall of the sleeve automatically removes adhered debris during pile-driving; the piston remains isolated from external environments during pile-driving operations, theoretically reducing scratch rates by over 90%.

Dual-Chamber Pressure Optimization:

Heavy-duty pile pressing "withstands pressure," force balance "resistant to deformation."

During the pile pressing process, the static pile driver must withstand axial pressures ranging from 800KN to 8600KN. Traditional hydraulic cylinders are prone to bending of the piston rod and deformation of the cylinder body due to concentrated stress, which can subsequently affect the accuracy of pile pressing.

The ZYC series is specifically designed for heavy-duty applications like pile drivers, with its core innovations being "inverted force application + dual-chamber pressure-bearing." First, the inverted force application shifts the key load-bearing point from the plunger to the robust cylinder body and protective sleeve. The plunger only needs to handle vertical pressure, reducing bending stress by 60%. Additionally, a groundbreaking design incorporates an inner cylinder within the hollow piston rod. By combining the pressure oil from the outer and inner cylinders, the effective load-bearing area increases by 40%. Even under ultra-high pressure of 5,000 kN, cylinder deformation remains controlled within 0.1 mm—this precision ensures no impact on the accuracy of pile pressing.

Composite Sealing System:

"Oil-proof" under high temperature and pressure, "No shutdown" during continuous operation

On the other hand, due to oil temperature rise and pressure fluctuations during the continuous operation of static pile drivers, traditional seals are prone to aging and leakage.

ZYC Series Customized "Rubber + Polyurethane" Composite Sealing System: The inner rubber ring utilizes elastic deformation to adapt to pressure fluctuations, while the outer polyurethane oil seal ring boasts wear resistance three times that of ordinary rubber and high-temperature tolerance, forming a "wear-resistant + heat-resistant" dual protection. The sealing groove is designed with thermal compensation space, flexibly accommodating the expansion and contraction of sealing components due to oil temperature changes, effectively solving leakage issues under high pressure and high temperature.

Browse more details of the Hydraulic static pile driver:https://www.t-works.cc/products

Conclusion: Empowering Efficient and Reliable Pile Foundation Construction with Customized Design

The ZYC series inverted oil cylinder static pressure pile driver addresses the operational needs of the industry by tackling three core pain points: "anti-contamination, heavy-duty resistance, and leak prevention." Through structural innovation, it builds durability advantages. Tianwei makes the static pressure pile driver your reliable partner.